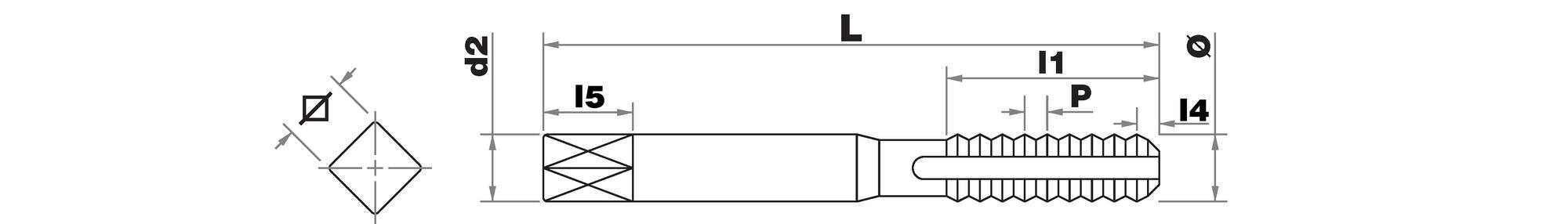

Multi-application machine tap HSSE-PM -TIN 20 coated -M -DIN 371/376 -Thread-former -6GX -Grooved

Référence : 960SRG1

Stock disponible

Stock mis à jour quotidiennement à 2h00Voir toutes les tailles

Présentation

Bénéfices

"By deformation" tap (sintered steel) for steels, stainless steels and cast iron. TiN 20 coating gives it an increased service life and high resistance to abrasion.

- Acier fritté ASP

- TiN20 coating

MACHINE

-

CNC numerical control

CNC numerical control

-

Machine conventionnelle

Machine conventionnelle

Geometry

-

Acier fritté + Cobalt

Acier fritté + Cobalt

-

Pas Métrique

Pas Métrique

-

Revêtement TiN 20

Revêtement TiN 20

-

Tolérance 6GX

Tolérance 6GX

-

DIN 371/376 norm

DIN 371/376 norm

-

Entrée forme C / 2-2,5 hls

Entrée forme C / 2-2,5 hls

-

Taraud à refouler

Taraud à refouler

-

With square drive (tap)

With square drive (tap)

-

Application

-

K3- Nodular and GS Cast iron

K3- Nodular and GS Cast iron

-

P- Ferrous Long Chip Steels

P- Ferrous Long Chip Steels

Demandes

Sector of Activity

-

Aeronautics

-

Automotive

-

General mechanic

-

Nautical

-

Transportation

-

Distributer

Properties

-

Acier fritté ASP : issus de la métallurgie des poudres, les ASP offrent une haute teneur en alliages extrêmement homogène, excellents supports pour les revêtements PVD.

-

TiN20 coating : Hardness 2300HV, coefficient of friction 0,60, resistance to heat (600°C).

+ Lister tous les produits 960SRG1

Liste des articles : 960SRG1