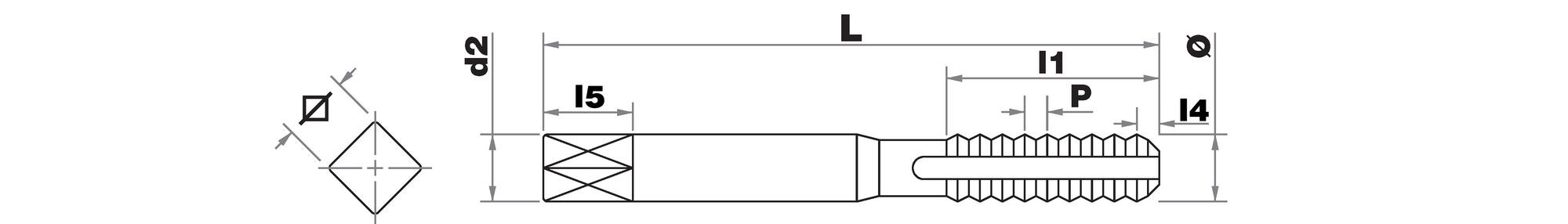

Flashcut machine tap HSSE-PM -TiN coated -M MF -DIN 371/374/376 -B Shape (GUN) -Interrupted thread -Rear conicity

Référence : 960AT21

Stock disponible

Stock mis à jour quotidiennement à 2h00Voir toutes les tailles

Présentation

Bénéfices

High performance tap (sintered steel) for aluminium alloys. Particularly suitable for through taps thanks to its Gun entry.

- Acier fritté ASP

- Denture alternée

- GUN entry

- TiN coating

MACHINE

-

CNC numerical control

CNC numerical control

-

Machine conventionnelle

Machine conventionnelle

Geometry

-

Acier fritté + Cobalt

Acier fritté + Cobalt

-

Pas Métrique / Métrique Fin

Pas Métrique / Métrique Fin

-

TiN coating

TiN coating

-

Tolerance

Tolerance

-

DIN 371/374/376 norm

DIN 371/374/376 norm

-

Entrée forme B "GUN" / 4-4,5 hls

Entrée forme B "GUN" / 4-4,5 hls

-

Entrée GUN

Entrée GUN

-

With square drive (tap)

With square drive (tap)

-

Denture alternée

Denture alternée

-

Application

-

N1-1- Aluminum-Series 1000 Alloy: Pure

N1-1- Aluminum-Series 1000 Alloy: Pure

-

N1-2- Aluminum-Series 2000 Alloy: with copper

N1-2- Aluminum-Series 2000 Alloy: with copper

-

N1-3- Alloy based on aluminum-series 3000: with manganese

N1-3- Alloy based on aluminum-series 3000: with manganese

-

N1-5- Aluminum-Series 5000 Alloy: with magnesium

N1-5- Aluminum-Series 5000 Alloy: with magnesium

-

N1-6-Alloy-based aluminum-series 6000: with magnesium and silicon

N1-6-Alloy-based aluminum-series 6000: with magnesium and silicon

-

N1-7- Aluminum-Series Alloy 7000: With Zinc

N1-7- Aluminum-Series Alloy 7000: With Zinc

Demandes

Sector of Activity

-

Automotive

-

General mechanic

-

Distributer

Properties

-

Acier fritté ASP : issus de la métallurgie des poudres, les ASP offrent une haute teneur en alliages extrêmement homogène, excellents supports pour les revêtements PVD.

-

Denture alternée : sur le sommet du taraud, une dent sur deux est tronquée pour réduire le contact outil/matière tout en maintenant le guidage.

-

Gun entry: entry geometry consisting of facets shaped to guide debris towards the front. Improves threading efficiency and precision.

-

TiN coating: TiN base, thickness 2/4µm, hardness 2300HV, coefficient of friction 0.4, heat resistance 600°C. Protects against abrasion, oxidisation, adhesion.

+ Lister tous les produits 960AT21

Liste des articles : 960AT21