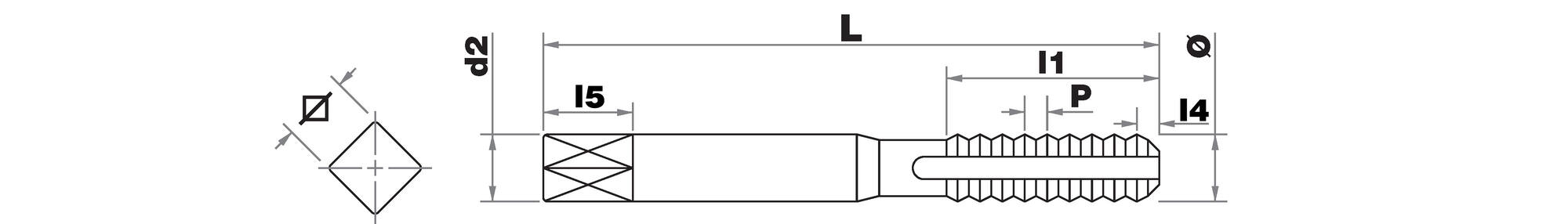

Standard machine tap HSS-E5 (cobalt 5%) -STEAM treatment -M MF -DIN 371 -Straight -6H -Reinforced shank

Référence : 9602411

Stock disponible

Stock mis à jour quotidiennement à 2h00Voir toutes les tailles

Présentation

Bénéfices

Tap for cast iron. Reinforced tail.

- 5% cobalt HSS

- Queue renforcée

- STEAM treatment

MACHINE

-

Machine conventionnelle

Machine conventionnelle

-

Drill press

Drill press

Geometry

-

High speed steel Cobalt 5% (tool material)

High speed steel Cobalt 5% (tool material)

-

Pas Métrique / Métrique Fin

Pas Métrique / Métrique Fin

-

Steam Nitriding coating

Steam Nitriding coating

-

Tolerance

Tolerance

-

DIN 371 norm

DIN 371 norm

-

Entrée forme C / 2-2,5 hls

Entrée forme C / 2-2,5 hls

-

-

With square drive (tap)

With square drive (tap)

-

Application

-

K1- Malleable Cast iron

K1- Malleable Cast iron

-

K2- Gray Cast iron

K2- Gray Cast iron

-

K3- Nodular and GS Cast iron

K3- Nodular and GS Cast iron

-

K4- CGI Cast Iron

K4- CGI Cast Iron

Demandes

Sector of Activity

-

Automotive

-

General mechanic

-

Distributer

Properties

-

5% cobalt high-speed steel: HSS substrate enriched with 5% cobalt. Improved heat retention (strength, cutting sharpness)

-

Queue renforcée : la queue du taraud est épaulée, soit plus large que le diamètre nominal.

-

STEAM treatment : Steam oxidation treatment.

+ Lister tous les produits 9602411

Liste des articles : 9602411