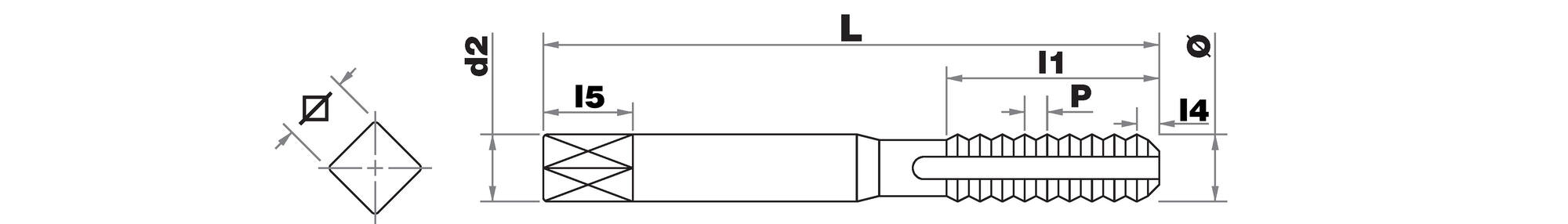

Multi-application machine tap HSS-E5 (cobalt 5%) -STEAM treatment -M MF -ISO 371 -B shape (GUN) -6H -Rear conicity -Reinforced shank

Référence : 9602021

Stock disponible

Stock mis à jour quotidiennement à 2h00Voir toutes les tailles

Présentation

Bénéfices

Tap, Multi-application. Particularly suitable for through tapping due to its Gun entry

- GUN entry

- 5% cobalt HSS

- Queue renforcée

- STEAM treatment

MACHINE

-

CNC numerical control

CNC numerical control

-

Machine conventionnelle

Machine conventionnelle

-

Drill press

Drill press

Geometry

-

High speed steel Cobalt 5% (tool material)

High speed steel Cobalt 5% (tool material)

-

Pas Métrique / Métrique Fin

Pas Métrique / Métrique Fin

-

Steam homo surface treatment

Steam homo surface treatment

-

Tolerance

Tolerance

-

DIN 371 norm

DIN 371 norm

-

Entrée forme B "GUN" / 4-4,5 hls

Entrée forme B "GUN" / 4-4,5 hls

-

Entrée GUN

Entrée GUN

-

With square drive (tap)

With square drive (tap)

-

denture à conicité arrière

denture à conicité arrière

-

Application

-

K1- Malleable Cast iron

K1- Malleable Cast iron

-

K3- Nodular and GS Cast iron

K3- Nodular and GS Cast iron

-

M2- Super austenitic stainless steels

M2- Super austenitic stainless steels

-

M3- Ferritic duplex stainless steels

M3- Ferritic duplex stainless steels

-

P- Ferrous Long Chip Steels

P- Ferrous Long Chip Steels

Demandes

Sector of Activity

-

Aeronautics

-

Automotive

-

General mechanic

-

Distributer

Properties

-

Gun entry: entry geometry consisting of facets shaped to guide debris towards the front. Improves threading efficiency and precision.

-

5% cobalt high-speed steel: HSS substrate enriched with 5% cobalt. Improved heat retention (strength, cutting sharpness)

-

Queue renforcée : la queue du taraud est épaulée, soit plus large que le diamètre nominal.

-

STEAM treatment : Steam oxidation treatment.

+ Lister tous les produits 9602021

Liste des articles : 9602021